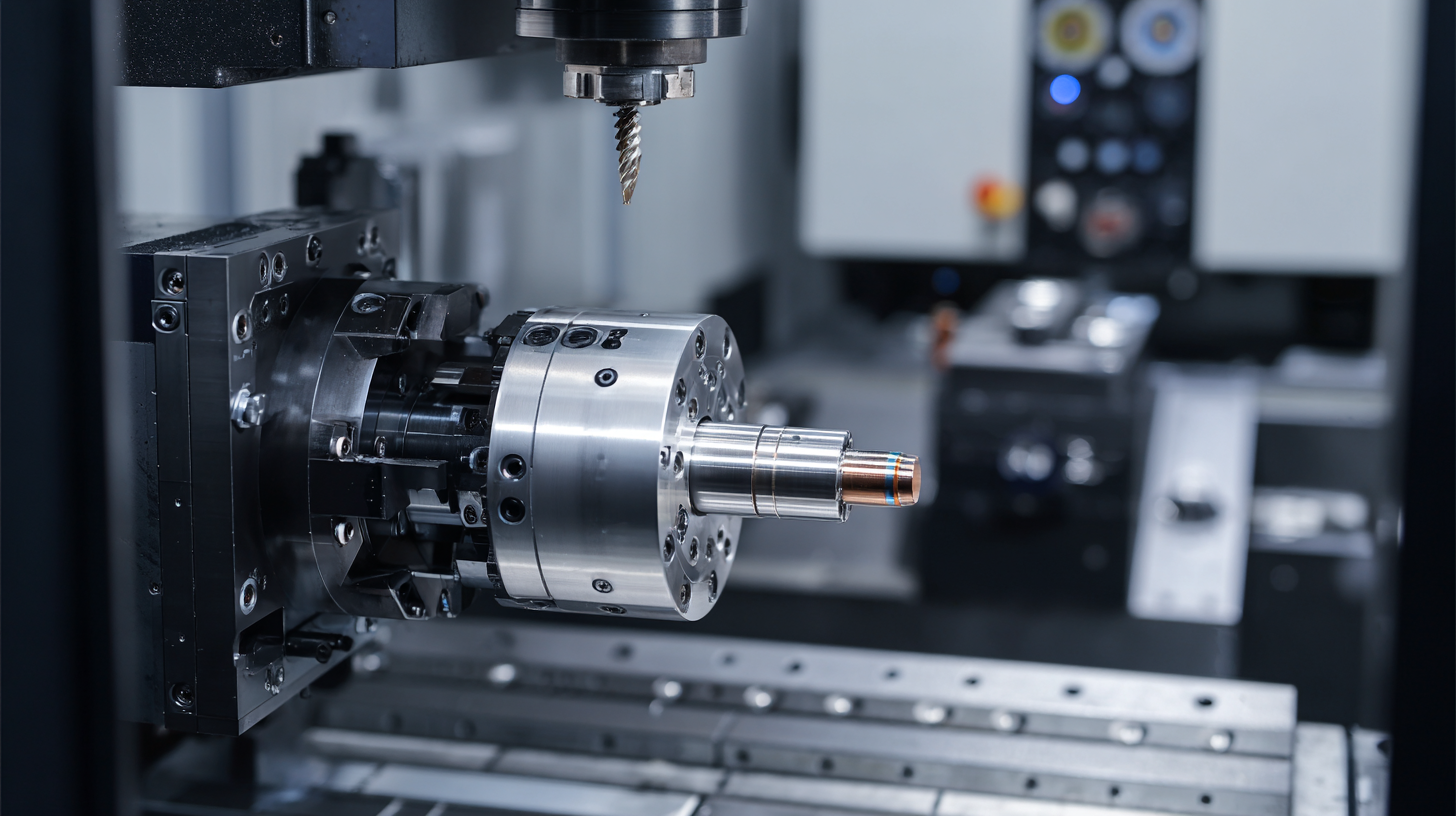

Unlocking Precision Manufacturing 7 Data Driven Insights for Optimal Production Efficiency

In the realm of Precision Manufacturing, leveraging data-driven insights has become pivotal for enhancing production efficiency. According to a report from Deloitte, manufacturers that adopt advanced analytics see a potential boost in productivity by up to 20%, significantly impacting their bottom line. Moreover, a McKinsey study highlights that businesses employing data science in their operations can achieve a 5-10% increase in operational efficiency within two years. As the competition intensifies and consumer demands evolve, it is critical for manufacturers to harness these insights to streamline processes, reduce waste, and optimize resource allocation. This article explores seven actionable data-driven insights that can redefine production strategies, ensuring that stakeholders remain at the forefront of the Precision Manufacturing landscape.

Leveraging Real-Time Analytics for Enhanced Operational Decision-Making

Real-time analytics has emerged as a game-changer in precision manufacturing, enabling companies to enhance operational decision-making and streamline production processes. According to a report by McKinsey, organizations that utilize real-time data analytics can increase operational efficiency by up to 20-30%. This significant improvement is attributed to the ability to monitor production lines continuously, allowing for immediate adjustments to be made when anomalies occur. As a result, manufacturers can reduce downtime and optimize resource allocation, leading to increased throughput and overall productivity.

Furthermore, leveraging real-time analytics can offer unprecedented insights into supply chain dynamics. A study by Deloitte highlights that manufacturers who integrate data-driven insights into their operations can boost their supply chain efficiency by as much as 25%. By analyzing real-time data on inventory levels, demand fluctuations, and production schedules, firms can make more informed, faster decisions that align resources with market needs. This proactive approach not only minimizes waste but also supports better forecasting, ultimately positioning manufacturers to respond swiftly to market changes while maintaining high quality and efficiency.

Unlocking Precision Manufacturing: 7 Data Driven Insights for Optimal Production Efficiency

| Insight | Description | Impact on Production Efficiency | Real-Time Analytics Tool |

|---|---|---|---|

| Predictive Maintenance | Utilizing sensors and monitoring equipment to predict failures before they occur. | Reduces downtime by 30% and maintenance costs by 20%. | DataRobot |

| Supply Chain Optimization | Analyzing supply chain data to improve procurement and delivery schedules. | Increases responsiveness by 25% and reduces inventory costs by 15%. | Tableau |

| Quality Control Automation | Automating quality inspections with machine learning algorithms. | Improves product quality by 40% and decreases rework time. | IBM Watson |

| Energy Management | Monitoring real-time energy consumption to identify savings opportunities. | Can reduce energy usage by 15% and lower utility costs. | EnergyHub |

| Workforce Productivity Analysis | Assessing worker performance through data and analytics. | Boosts productivity by 20% and enhances employee engagement. | Microsoft Power BI |

| Product Lifecycle Management | Using data analytics to manage the lifecycle of a product effectively. | Can reduce time-to-market by 30% and product development costs. | Siemens Teamcenter |

| Real-Time Production Monitoring | Tracking production processes live to identify bottlenecks. | Enhances throughput by 35% and optimizes resource allocation. | Aegis FactoryLogix |

Implementing Predictive Maintenance to Minimize Downtime and Costs

Predictive maintenance is revolutionizing the landscape of precision manufacturing by minimizing downtime and reducing operational costs. By harnessing data analytics and machine learning algorithms, manufacturers can predict equipment failures before they occur, allowing for timely interventions. This proactive approach not only enhances equipment life but also optimizes production schedules, ensuring that the manufacturing process runs smoothly without unexpected interruptions.

The implementation of predictive maintenance entails gathering data from various sensors and systems within the manufacturing environment. Advanced analytics converts this data into actionable insights, identifying patterns that signify potential breakdowns. As a result, manufacturers can strategically plan maintenance activities during non-peak hours, which leads to significant cost savings. Furthermore, this data-driven method fosters a culture of continuous improvement, enabling organizations to refine their processes and enhance overall efficiency. With predictive maintenance at the forefront, manufacturers can achieve unprecedented levels of operational excellence.

Utilizing Big Data to Optimize Supply Chain Efficiency and Reduce Waste

In today's manufacturing landscape, leveraging big data has become essential for optimizing supply chain efficiency and minimizing waste. According to a report by McKinsey & Company, companies that utilize data analytics within their supply chains can reduce operational costs by up to 15% and enhance overall productivity by 20%. This significant improvement stems from the ability to predict demand accurately and manage inventory levels effectively, ensuring that resources are utilized optimally while avoiding overproduction.

Furthermore, a study conducted by the Institute for Supply Management highlights that organizations tapping into data-driven decision-making can decrease waste by approximately 30%. By employing advanced analytics, manufacturers can identify inefficiencies, from procurement practices to logistics, and implement real-time solutions. Technologies such as IoT devices can collect granular data along the supply chain, which not only aids in forecasting but also in tracking products, thereby reducing spoilage and excess inventory.

As companies transition to more data-centric approaches, the potential for achieving a leaner, more efficient manufacturing process will only continue to expand.

Adopting Smart Automation for Improved Accuracy and Production Speed

The rise of smart automation is revolutionizing precision manufacturing, offering unprecedented accuracy and production speed. According to a report by McKinsey, automation has the potential to increase productivity by 20% to 30% in manufacturing settings. By integrating advanced technologies such as robotics, IoT, and AI, manufacturers can streamline operations, reduce human error, and enhance overall production efficiency. This shift towards intelligent systems not only speeds up production cycles but also allows for real-time data analysis and decision-making, ensuring optimal performance.

Tip: Begin by assessing your current production processes to identify areas where automation can deliver the most impact. Implementing small-scale pilot projects can help smooth the transition and gauge the benefits before full-scale deployment.

Additionally, a study from Deloitte highlights that companies utilizing smart automation can achieve a 15% reduction in operational costs. With precise data analytics, manufacturers can predict maintenance needs, minimize downtimes, and tailor production schedules to match demand fluctuations effectively. This adaptability is crucial for maintaining a competitive edge in today’s fast-paced market.

Tip: Invest in training your workforce to work alongside automated systems. A skilled team that understands both technology and production processes is integral to maximizing the benefits of smart automation.

Integrating IoT Technologies for Seamless Data Collection and Insights

The integration of IoT technologies in the manufacturing sector is revolutionizing data collection and operational efficiency. As the global IoT market in manufacturing is projected to reach $97.03 billion in 2023, with a significant increase to $673.95 billion by 2032, the emphasis on real-time data analysis and seamless connectivity becomes paramount. These advancements empower manufacturers to gather critical insights, enabling them to optimize production processes effectively.

Furthermore, as industries embrace Industry 4.0 practices, the market is expected to expand from $130.9 billion in 2022 to $377.33 billion by 2029. This growth, fueled by a compound annual growth rate of 16.3%, highlights the increasing reliance on IoT platforms for efficient data management. The introduction of smart devices and data collection technologies enhances decision-making, allowing manufacturers to adapt swiftly to changing market conditions and advance towards a more interconnected and intelligent production landscape.

Related Posts

-

Top Strategies for Sourcing the Best Precision Tools for Global Supply Chains

-

How to Choose the Best Precision Manufacturing Partner for Your Global Supply Chain

-

Common Issues Facing the CNC Equipment Industry and Their Impact on Production Efficiency

-

Top 10 CNC Milling Machine Manufacturers from China at the 137th Canton Fair

-

A Comprehensive Comparison of Machining Costs Across Different Industries and Technologies

-

Real-World Applications of Best CNC Machining: How Precision Manufacturing Transforms the Aerospace Industry