Ultimate Checklist for Sourcing the Best Precision Tools: Key Metrics and Supplier Insights

As industries evolve towards greater efficiency and innovation, the demand for high-quality precision tools continues to surge. A recent report from Market Research Future indicates that the global precision tools market is projected to reach a staggering $18 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.5%. This increase is driven by advancements in technology and the rising need for accuracy in manufacturing processes across various sectors, including aerospace, automotive, and electronics. To navigate this dynamic landscape, it becomes crucial for businesses to source the best precision tools that meet their specific requirements. This blog presents an ultimate checklist, focusing on key metrics for evaluating suppliers and insights into industry trends, empowering organizations to make informed decisions in their procurement strategies for precision tools.

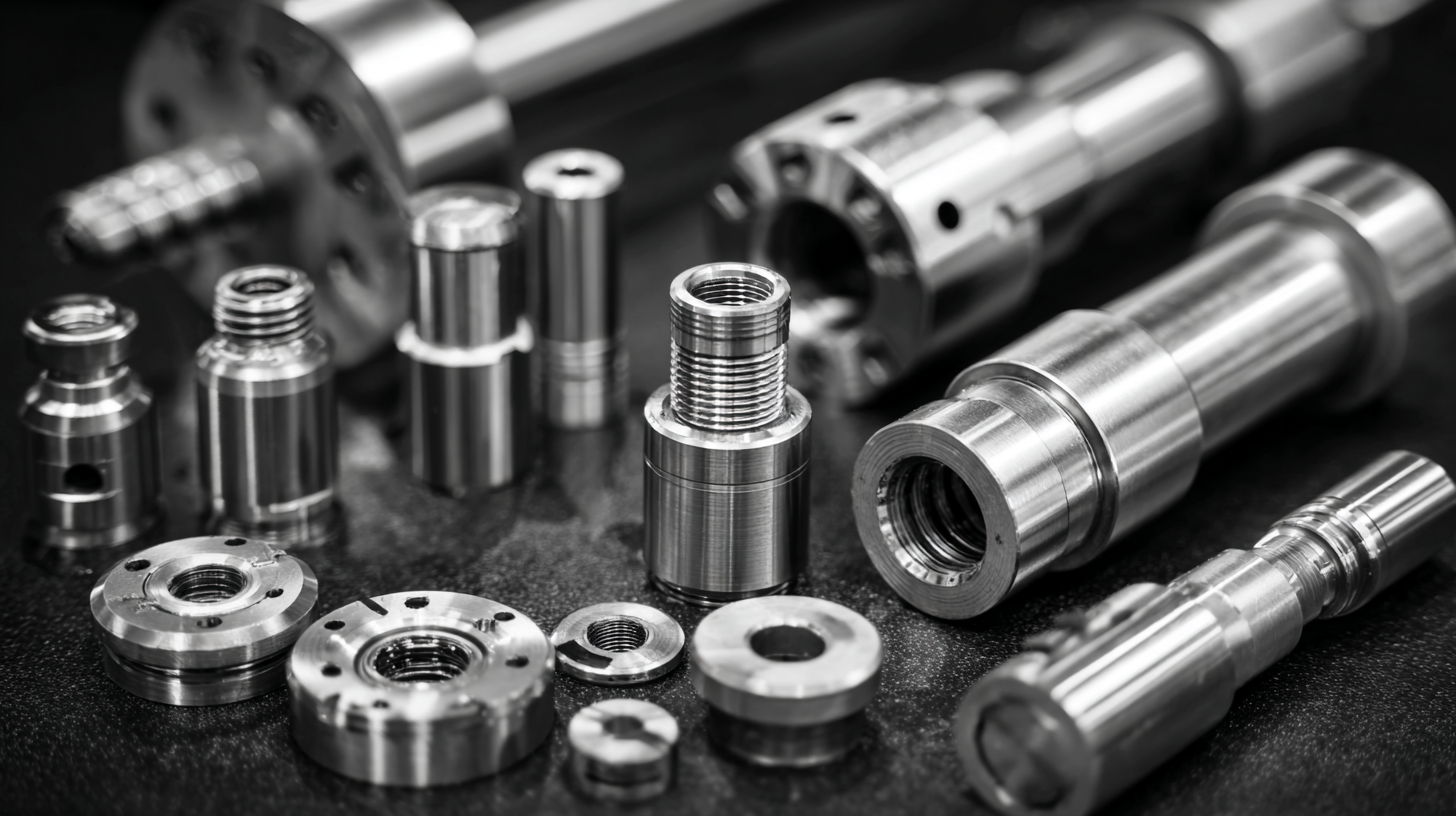

Identifying Essential Precision Tool Metrics for Optimal Performance

When sourcing precision tools, understanding key metrics is crucial for optimal performance. According to a report by MarketsandMarkets, the global precision tools market is expected to reach $15.1 billion by 2025, growing at a CAGR of 6.5%. This significant growth underscores the importance of identifying metrics that measure tool reliability, accuracy, and durability.

One essential metric is the tool's tolerance level, which specifies how much variation in dimensions is permissible. Tighter tolerances often indicate higher quality tools, which can lead to better end-product precision, ultimately reducing waste and increasing efficiency. Additionally, the tool life expectancy plays a critical role; data from the Association for Manufacturing Technology indicates that a 10% increase in tool longevity can reduce production costs by nearly 15%. This correlation highlights the necessity for suppliers to provide comprehensive life cycle data to ensure long-term value.

Moreover, evaluating the supplier's history of delivery performance and customer satisfaction ratings can provide insights into their reliability. A survey by the Precision Metalforming Association found that over 70% of manufacturers regard timely delivery as a pivotal factor when choosing a tool supplier. By focusing on these key metrics, manufacturers can enhance their sourcing strategies and achieve superior operational results.

Evaluating Supplier Credentials: What to Look For

When sourcing precision tools, evaluating supplier credentials is a critical step that can significantly impact your project’s success. First, consider the supplier’s experience in the industry. A supplier with a proven track record typically demonstrates reliability and expertise. Look for certifications relevant to precision tools, such as ISO or other industry-specific standards, as these indicate adherence to quality control processes. An established reputation can often be gauged from reviews, testimonials, and case studies presented on their website.

When sourcing precision tools, evaluating supplier credentials is a critical step that can significantly impact your project’s success. First, consider the supplier’s experience in the industry. A supplier with a proven track record typically demonstrates reliability and expertise. Look for certifications relevant to precision tools, such as ISO or other industry-specific standards, as these indicate adherence to quality control processes. An established reputation can often be gauged from reviews, testimonials, and case studies presented on their website.

Next, assess the supplier’s technical capabilities and range of offerings. Suppliers should have the latest technology and materials to ensure that the tools meet the desired specifications and performance standards. It’s also important to explore their customer support services and warranty policies. A supplier that provides comprehensive support and stands behind their products is invaluable when unforeseen issues arise. Engaging directly with potential suppliers through discussions about your specific requirements can provide further insight into their commitment to quality and service, helping you make an informed decision.

Comparative Analysis of Precision Tool Materials and Their Impact

When sourcing precision tools, the choice of materials plays a crucial role in determining their performance and longevity. Different materials such as high-speed steel, carbide, and ceramic each bring unique strengths to precision applications. High-speed steel, for instance, is favored for its toughness and resistance to breakage, making it ideal for tools that require resilience under high pressure. Conversely, carbide tools provide exceptional hardness and wear resistance, allowing them to maintain cutting edges for extended periods, thus reducing downtime and increasing productivity.

Comparative analysis of these materials reveals significant differences in their impact on machining processes. While high-speed steel tools may be more economical and effective for softer materials, carbide tools excel when working with harder substrates. Additionally, ceramic tools are increasingly gaining traction due to their lightweight nature and resistance to thermal deformation, making them suitable for high-speed applications. Understanding these material properties not only aids in selecting the right tools but also enhances machining efficiency and product quality. Ultimately, the right material can significantly influence the overall effectiveness and cost-effectiveness of precision tooling solutions.

Ultimate Checklist for Sourcing the Best Precision Tools

Emerging Trends in Precision Tool Technology and Their Implications

The landscape of precision tool technology is rapidly evolving, significantly impacting the healthcare sector. As we approach 2025, several emerging trends are shaping how precision medicine is administered. One of the most notable trends is the integration of artificial intelligence (AI) into diagnostic and treatment processes, with a recent report indicating that over 70% of healthcare organizations plan to adopt AI solutions by 2025. This shift allows for the analysis of vast datasets to personalize patient care and enhance treatment efficacy, ultimately driving better outcomes.

Another key trend is the rise of wearable technology, which is projected to reach a market value of $60 billion by 2025. These devices provide real-time health monitoring, allowing for continuous data collection and immediate insights into patient conditions. This trend empowers healthcare providers to transition from reactive to proactive care, ensuring timely interventions tailored to individual patient needs. Furthermore, advancements in genomics are paving the way for personalized therapies, with a forecast suggesting that precision therapies will account for a significant portion of new treatment protocols in the coming years. The convergence of these technologies is unlocking unprecedented opportunities for targeted, data-driven care, fundamentally transforming healthcare delivery.

Building Long-Lasting Partnerships with Precision Tool Suppliers

Building long-lasting partnerships with precision tool suppliers is crucial for companies aiming to enhance their operational efficiency and product quality. A report by MarketsandMarkets estimates that the precision tools market will reach $23.4 billion by 2025, driven by the growing demand for automation and precision engineering across various industries. This trend emphasizes the need for businesses to forge strategic alliances with suppliers who understand their specific needs and can provide tailored solutions.

Moreover, a study by McKinsey highlights that companies that prioritize collaborative relationships with suppliers benefit from reduced costs and improved innovation, with performance improvements of up to 30%. Engaging with suppliers in a meaningful way involves not just transactional interactions but also regular communication and feedback that foster trust and cooperation. By leveraging data analytics and performance metrics, organizations can identify and work with suppliers who consistently deliver quality and innovation, ensuring that both parties thrive in an increasingly competitive landscape.