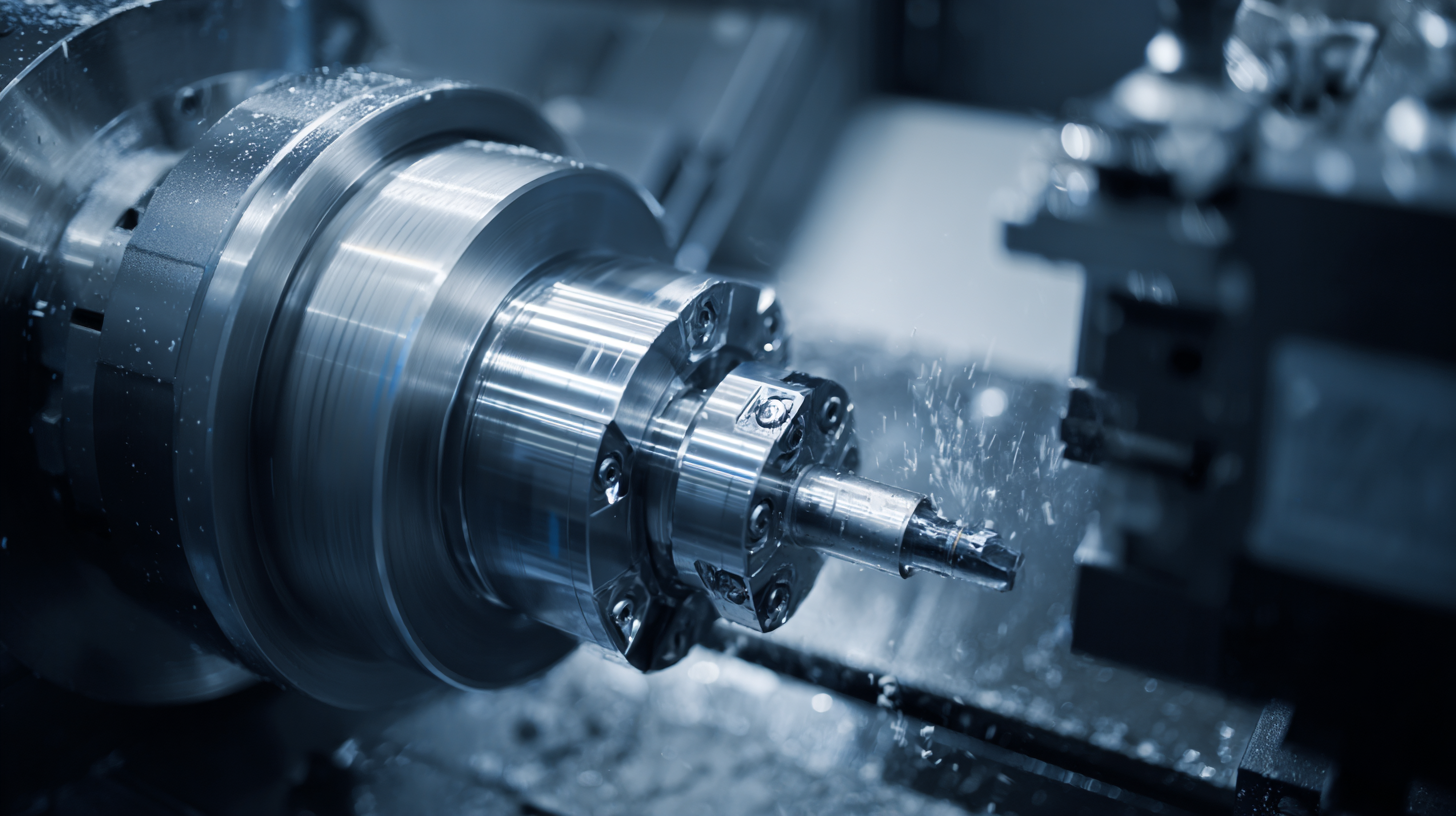

Maximizing Efficiency with the Best Cnc Machining Centers in Modern Manufacturing

In the rapidly evolving landscape of modern manufacturing, the significance of efficiency cannot be overstated. A recent report by the International Federation of Robotics indicates that the use of CNC machining centers has increased by 15% annually, underscoring their pivotal role in enhancing productivity and precision. These advanced machines enable manufacturers to streamline operations, reduce lead times, and minimize waste, making them indispensable in competitive sectors like aerospace and automotive. As companies strive to stay ahead in an increasingly global market, adopting the best CNC machining centers not only supports cost-effective production but also enhances overall operational agility. This blog explores the characteristics and advantages of cutting-edge CNC machining centers, demonstrating how they can facilitate greater efficiency and innovation in manufacturing processes.

Future-Driven CNC Machining Centers: Key Features Shaping 2025 Innovations

As we approach 2025, the evolution of CNC machining centers is set to redefine efficiency and innovation in modern manufacturing. Key features driving these advancements include the integration of artificial intelligence (AI), the Internet of Things (IoT), and robotics. These cutting-edge technologies facilitate real-time monitoring and predictive maintenance, significantly reducing downtime and enhancing production quality. A recent report anticipates that the market for 3-Axis and 5-Axis CNC Vertical Machining Centers will reach USD 11.41 billion by 2024, with steady growth projected in the following years as manufacturers increasingly adopt these advanced solutions.

Furthermore, the rise of digitalization in the machine tool industry is transforming traditional manufacturing paradigms. Advanced CNC machining centers are now more connected, allowing for seamless data exchange across the supply chain. This connectivity not only bolsters supply chain resilience but also aids in lowering carbon footprints, responding to the growing demand for sustainable manufacturing practices. As manufacturers invest in these future-driven CNC solutions, the landscape of industrial automation is set to change dramatically, marking a new era of manufacturing excellence.

Maximizing Efficiency with the Best CNC Machining Centers

This chart illustrates the key performance metrics for modern CNC Machining Centers, highlighting their speed, accuracy, load capacity, and energy consumption in a comparative format. These metrics are crucial for understanding how innovations in CNC technology will drive efficiency in manufacturing by 2025.

The Impact of Advanced Automation on CNC Machining Efficiency in 2025

As we look toward 2025, the intersection of advanced automation and CNC machining is set to revolutionize manufacturing efficiency. According to a recent report from MarketsandMarkets, the CNC machining market is projected to grow from $73.42 billion in 2020 to $102.62 billion by 2025, with automation technologies driving a significant portion of this growth. Automated CNC machining centers are optimizing production processes by reducing human error and enhancing operational speed.

The integration of artificial intelligence and machine learning into CNC systems is redefining efficiency metrics. A study by Deloitte indicates that manufacturers adopting these advanced technologies can achieve up to a 30% decrease in operational downtime while improving overall productivity by 20%. With predictive maintenance and real-time monitoring capabilities, CNC machining centers can now operate at peak performance, allowing manufacturers to meet the increasing demand for precision-engineered components rapidly. As these technologies mature, companies that invest in automation will not only enhance their competitive edge but also contribute to a sustainable manufacturing future.

Incorporating IoT: Enhancing Real-Time Monitoring for CNC Processes

In the realm of modern manufacturing, the integration of Internet of Things (IoT) technology into CNC machining processes has revolutionized how companies monitor and manage their operations. By incorporating IoT devices, manufacturers can achieve real-time data collection and analysis, which enhances the visibility of machine performance, production efficiency, and overall workflow. This kind of connectivity allows operators to identify bottlenecks promptly, predict maintenance needs, and streamline processes based on data-driven insights.

Moreover, the real-time monitoring capabilities enabled by IoT can significantly reduce downtime and improve product quality. Sensors can detect deviations from normal operating conditions, alerting staff to potential issues before they escalate. This proactive approach not only optimizes machine utilization, but it also enhances responsiveness to manufacturing demands. As CNC machining centers become increasingly automated and interconnected, the ability to harness and analyze vast amounts of data in real-time will be critical for staying competitive in the fast-paced manufacturing landscape.

Adopting Sustainable Manufacturing Practices in CNC Machining Facilities

As manufacturers strive for efficiency in CNC machining, adopting sustainable practices is emerging as both a necessity and a competitive advantage. Implementing environmentally friendly methods not only reduces waste but also aligns with the growing consumer demand for responsible production. By utilizing energy-efficient machines and renewable materials, facilities can minimize their carbon footprint while enhancing productivity.

**Tips for Sustainable CNC Machining:**

- Consider upgrading to CNC machines with high energy efficiency ratings. These machines consume less power and can significantly lower operational costs.

- Implement a robust recycling program for scrap materials. This helps reduce landfill waste and can turn what was once considered waste into an additional revenue stream.

- Explore the use of biodegradable cutting fluids. These alternatives are not only better for the environment but can also improve the working conditions for machinists.

Additionally, investing in technology that monitors energy consumption in real-time can help facilities identify areas for improvement. By focusing on these sustainable practices, CNC machining companies can lead the way in modern manufacturing, ensuring they meet the demands of today’s eco-conscious market while maximizing their overall efficiency.

Maximizing Efficiency with the Best CNC Machining Centers in Modern Manufacturing

| CNC Machining Center Type | Max Cutting Speed (m/min) | Accuracy (mm) | Sustainable Features | Energy Efficiency (kWh) |

|---|---|---|---|---|

| Vertical Machining Center | 80 | 0.01 | LED lighting, Eco-friendly coolant | 5 |

| Horizontal Machining Center | 100 | 0.005 | Recuperative energy systems | 7 |

| 5-Axis CNC Machining Center | 120 | 0.002 | Recyclable materials used | 6 |

| CNC Router | 75 | 0.015 | Low-VOC paints | 4 |

Statistical Insights: Projected Market Growth and CNC Technological Advancements by 2025

The CNC machine market is set for significant growth in the coming years, with projections estimating an increase from $101.22 billion in 2025 to approximately $195.59 billion by 2032. This steady rise, with a compound annual growth rate (CAGR) of 9.9%, reflects the increasing demand for automation and precision in modern manufacturing processes. According to research findings, the CNC vertical machining center market alone is anticipated to reach $16.37 billion by 2034, growing at a rate of 5.36%. These trends underscore the pivotal role CNC technology plays in enhancing manufacturing efficiency.

Tips for manufacturers looking to optimize their CNC machining processes include investing in the latest CNC technologies and tools. Embracing advancements such as AI and IoT can further improve operational efficiencies. Additionally, periodic training of staff on new CNC equipment can ensure that teams are equipped with the right skills to maximize production capacity.

As the precision turned product manufacturing sector is predicted to hit USD 196.11 billion by 2034, businesses are advised to assess their current machining capabilities and upgrade where necessary. Regularly reviewing market trends and technological advancements will enable manufacturers to stay competitive and maintain high production efficiency.